3. Classification of extruder

& Classification of extruders: With the increase in the use of extruders, various extruders have appeared, and there are many classification methods.

&1 According to the number of screws, it can be divided into single-screw extruder and multi-screw extruder;

&2 According to the possibility of venting, it can be divided into venting extruder and non-venting extruder;

# ##&3 According to the existence of screw, it can be divided into screw extruder and screwless extruder;

&4 According to the position of the screw in the space, it can be divided into horizontal extruder and vertical extruder

& This chapter will introduce the above various extruders one by one.

The most commonly used is the horizontal single-screw non-porous extruder, this chapter will focus on the introduction.

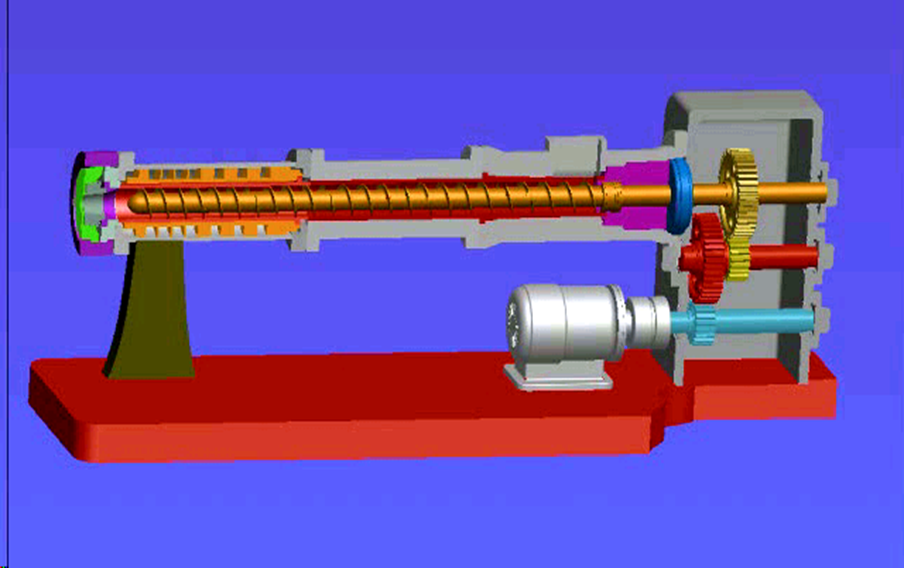

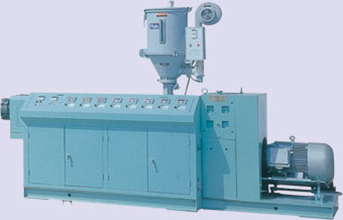

&Plastic extruder

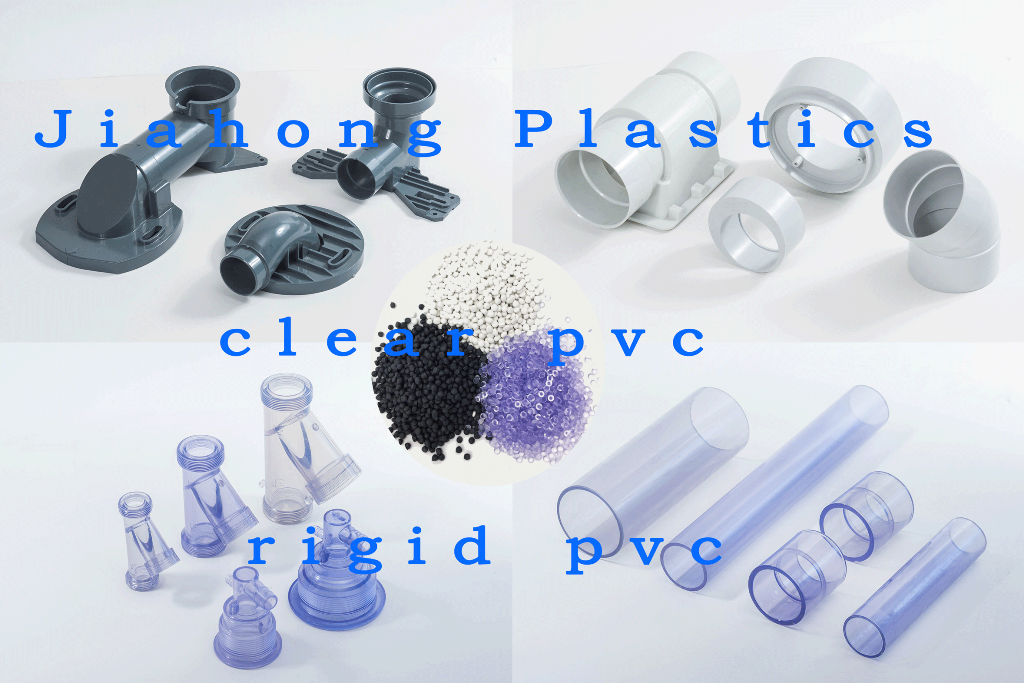

4. Main parameters of single screw extruder for rigid transparent PVC particles

The performance characteristics of a single screw extruder are usually represented by the following main technical parameters:

&Screw diameter: refers to the outer diameter of the screw, denoted by D, in millimeters.

American max750mm

&The ratio of screw length to diameter: expressed in L/D. Among them, L is the effective length of the screw, that is, the length of the threaded part. In this process, L is defined as the length from the centerline of the feed port to the end of the thread, and D is the diameter of the screw.

&Screw rotation range: expressed by n/min.\\r\\n

& Drive motor power: expressed by N, in kilowatts.

Germanyφ500-3600kwφ600-5000kw

&Barrel heating part number: denoted by B.

&Barrel heating power: Expressed by E, in kilowatts.

&Extruder productivity: expressed in Q, in kilograms per hour.

&The height of the center of the machine: expressed as H, which refers to the center line of the screw to the ground.

The unit is millimeters.

& Overall dimensions of the machine: length, width and height.

The unit is millimeters.

2.1 Working process of rigid transparent PVC pellet extruder

l The reason why plastic rubber can be molded and processed is due to its inherent dependence

According to the decision.

l It is known from polymer physics that polymers usually exist in a glassy state,

Three physical states of high elasticity and viscous flow. In some cases, this

These three physical states will switch to each other.

l Plastic rubber molding, pressing, calendering, extrusion and injection

Need to wait

1. Extrusion process

After the plastic rubber enters the barrel from the hopper, it is gradually pushed toward the head of the machine as the screw rotates.

Go through the following four stages:

l 1 Feeding section---transport and start compacting materials

The screw groove is filled with loose solid particles or powder, and

l 2 Compression section---compresses and melts the material

a. The material is compacted due to resistance

As the screw groove gradually becomes shallower, the filter screen, the manifold and

The resistance of the machine head creates a very high pressure in the plastic rubber, thereby squeezing the material very tightly.

l b. The action of external heat and internal heat causes the material to melt

The temperature of the plastic rubber gradually rises under the action of the external heat of the cylinder and the internal frictional heat generated by mixing and shearing.

For a conventional three-section full flight screw, which is about one-third of the compression section, the barrel wall reaches the viscous flow temperature and begins to melt at a certain point where the plastic and rubber come into contact with the contact point.

c. All materials melt and become a viscous fluid state

As the material is transported forward, the amount of molten material gradually increases.

The amount of unmelted material gradually decreases. At about the end of the compression section, all the materials melt and become a viscous fluid state, but the temperature at each point is not uniform at this time.

l 3 homogenization section---homogenization

After the homogenization section, the homogenization effect of the rigid transparent PVC granules is relatively uniform. Finally, the screw quantitatively squeezes the molten material into the die under a constant pressure and a constant pressure.

l 4 heads---molded and finalized

The mold in the machine head is a molded part through which the material obtains a certain cross-sectional geometry and size.

After cooling or vulcanization, the molded product can be obtained.

All in all, the extrusion process of the extruder can be summarized as follows:

Feeding hard transparent PVC granules-conveying-compacting-melting-homogenizing-extrusion molding